Choosing the Right Grapple For Your Compact Tractor

Picture this: You’re out with your compact tractor, trying to clear some brush, but your grapple is not able to grab a firm hold of the debris it’s trying to pick up. It’s not that you’re doing it wrong—most likely, you don’t have the right tool for the job.

From picking up piles of brush to carrying logs and rocks, grapples excel at securing debris so you can transport it easily, turning your compact tractor into a material-handling powerhouse. But grapples are specialized devices. You can’t use a brush grapple to pick up rocks, nor can a rock grapple be used to lift logs. Having the right grapple for the job can make for a productive day or an absolute waste of time and resources.

At Earth and Turf Attachments, we’ve been helping compact tractor operators maximize their productivity by designing specialized attachments to address unmet needs. In this blog, we’ll look at grapple attachments and how you can choose a grapple that matches your needs.

Types of Grapples: Which One Matches Your Workload?

Not all grapples are the same. There are several distinct types of specialized grapple attachments, each with its own design features and best use scenarios. Here we’ll cover four categories: root grapples, brush grapples, rock grapples, and multi-purpose grapples:

Root Grapples are designed for heavy-duty jobs, such as uprooting trees, hauling logs, and clearing storm debris. These have strong upper clamps and spaced lower tines that let dirt fall through while holding onto roots and large branches. If you’re digging in and hauling out, this is what you need.

Brush Grapples are designed for lighter work. Ideal for loose materials like twigs, hedge trimmings, or vineyard cuttings, they are typically lighter in weight, making them an excellent fit for sub-compact tractors. A wide jaw and dual clamps help gather more in one go, making for quick clearing work.

Rock Grapples are also known as skeleton grapples. These are built with closely spaced tines to sift soil and separate rocks or rubble. They’re heavy-duty and great for landscaping or clearing rocky fields—but make sure your tractor can handle the extra weight.

Multi-Purpose Grapples combine features from root, brush, and rock grapples, offering all-around performance. While they might not excel at one specific job, they’re perfect for users who need flexibility for mixed tasks around a farm or homestead.

Weight and Size Considerations

Compact tractors come with limited lift capacity, so you need to choose a grapple that won’t overload your machine before it even grabs a thing.

- Weight: Ensure the grapple is compatible with your tractor’s size and lift capacity. Grapple attachments range from lightweight models weighing around 200-300 lbs for sub-compact tractors to very heavy-duty ones weighing 800 lbs or more for large skid steers or full-size tractors. Most compact tractors can handle a grapple in the 300-to-500-pound range. If your grapple is too heavy, you’ll sacrifice lift capacity for the attachment itself.

- Width: Match or slightly exceed your tractor’s wheel width. If the grapple is too wide, it gets harder to maneuver. A grapple that’s too narrow won’t be able to grab anything securely. Grapple widths typically come in sizes of 48 inches, 60 inches, and 72 inches” with opening widths of 30-40 inches. A wider one can cover more ground when raking or collecting debris, but remember it will weigh more and might stick out past the tractor’s sides.

- Depth: A long grapple floor can hold more, but also moves the load farther forward, which can tip the balance (literally, or backward in this case). Keep loads close to your loader arms for better stability. A counterweight (also known as a ballast box) shifts the center of gravity back, allowing for a more balanced load and improved lifting capacity.

Finally, always check your loader’s lift specs, and be sure you’re leaving room for the load, not just the grapple.

Hydraulic Requirements: What You Need Before Hooking Up

Unlike a standard bucket that only uses your loader’s up/down and tilt functions, a grapple needs an additional hydraulic cylinder to open and close the jaws. Most modern compact tractors have a third-function hydraulic valve. If your machine doesn’t have one, you can install an aftermarket kit. Without it, your grapple has no way to open and close.

Other things to consider are:

- Hydraulic flow rate and pressure: Grapple cylinders don’t require a lot of flow like a hydraulic motor does, as even tractors with modest flow of 5-10 gallons per minute can operate a grapple, just at a slower open/close speed. As long as your tractor’s hydraulic system is stock, it will have enough power to operate any grapple designed for compact tractors.

- Hoses and couplers: Make sure they match your tractor’s connections. Many come with hoses and standard quick-connect couplers, but verify that they are compatible; you may also need adapters. For your sanity, pay attention to hose routing when you attach the grapple—you’ll want to secure hoses so they don’t get pinched when curling or snagged by branches during use. Secure them properly to avoid pinching or pulling.

Finally, if you need help with your hoses, make sure you get these Hosers, and not those Hosers!

Choosing the Best Grapple for Specific Jobs

Let’s break it down by task:

- Land Clearing & Tree Work: Use a root grapple. With strong clamps, open bottoms, and curved tines, root grapples make uprooting and hauling logs easy. For brute-force tasks like ripping out an old hedge or hauling off a tree you just cut down, a root grapple is hard to beat and is a rage room on wheels.

- Brush and Debris Removal: A brush grapple with dual clamps and wide openings works best. It’s light, fast, and built for volume, perfect for clearing fallen tree limbs, vines, and orchard prunings, or piling up autumn brush for burning. You can even rip out shallowly rooted shrubs.

- Landscaping & Rock Work: Choose a rock grapple. The tight tine spacing sifts soil and scoops rocks, perfect for fields or driveways. For landscaping tasks, you can do things like gathering medium-sized stones for a rock wall or removing debris while leveling the ground, since the tine spacing helps spread soil as you rake, almost like a land plane.

- General Farm Use: A multi-purpose grapple gives you flexibility—one tool to rule them all! Handle logs, brush, or even loose hay with ease. If you’re a homesteader who needs to do some of everything, a multipurpose grapple is for you.

Pick based on what you do most often—no need to overbuy for tasks you rarely tackle.

Maintenance and Longevity Tips

A grapple is a hard-working tool, but it needs care to stay in top shape. Here’s how:

- Grease all pivot points regularly. Quality grease, applied on a regular schedule—daily or every few hours of use—keeps the pins and bushings lubricated, ensuring smooth operation and preventing metal-on-metal wear that can enlarge holes or cause a hinge to seize.

- Check hydraulic hoses for signs of abrasion, pinching, or leaks. Ensure the hose clamps or guides are holding the lines away from pinch points when you curl or dump the loader. Make sure all quick-connect couplers are clean and fully seated. Replace any worn or cracked hoses promptly, and consider adding hose sleeves or guards if you notice rub spots.

- Inspect welds, bolts, and pins after tough jobs. Grapples take a lot of abuse when you’re biting into logs or shaking out rocks, so periodically inspect all the fasteners. Check that the central pivot pin retaining bolts or clips are secure. If your grapple has any bolted-on teeth, side plates, or replaceable cutting edges, verify that those bolts are tight. It’s not a bad idea to go over major nuts and bolts with a wrench once in a while to ensure nothing has loosened due to vibration.

- Clean off debris and store it off the ground if possible. After you finish a hard day of grappling, take a few minutes to clean off the attachment. Hardened mud or plant matter can hold moisture against metal, causing rust over time. If you’ve been handling sap-covered trees, a gentle solvent or degreaser can remove sticky residue that might otherwise attract dirt.

- Keep cylinders retracted when not in use to protect the rod. Leaving the cylinder fully extended exposes a lot of the polished rod to the elements, which can cause pitting. If you must leave it outside for an extended period, coating the rod with grease or a fluid film provides a protective layer.

Simple upkeep goes a long way in keeping your grapple reliable year after year. By storing the grapple properly, you’ll preserve its finish and functionality. When you hook it up next time, it’ll be ready to work without a hitch!

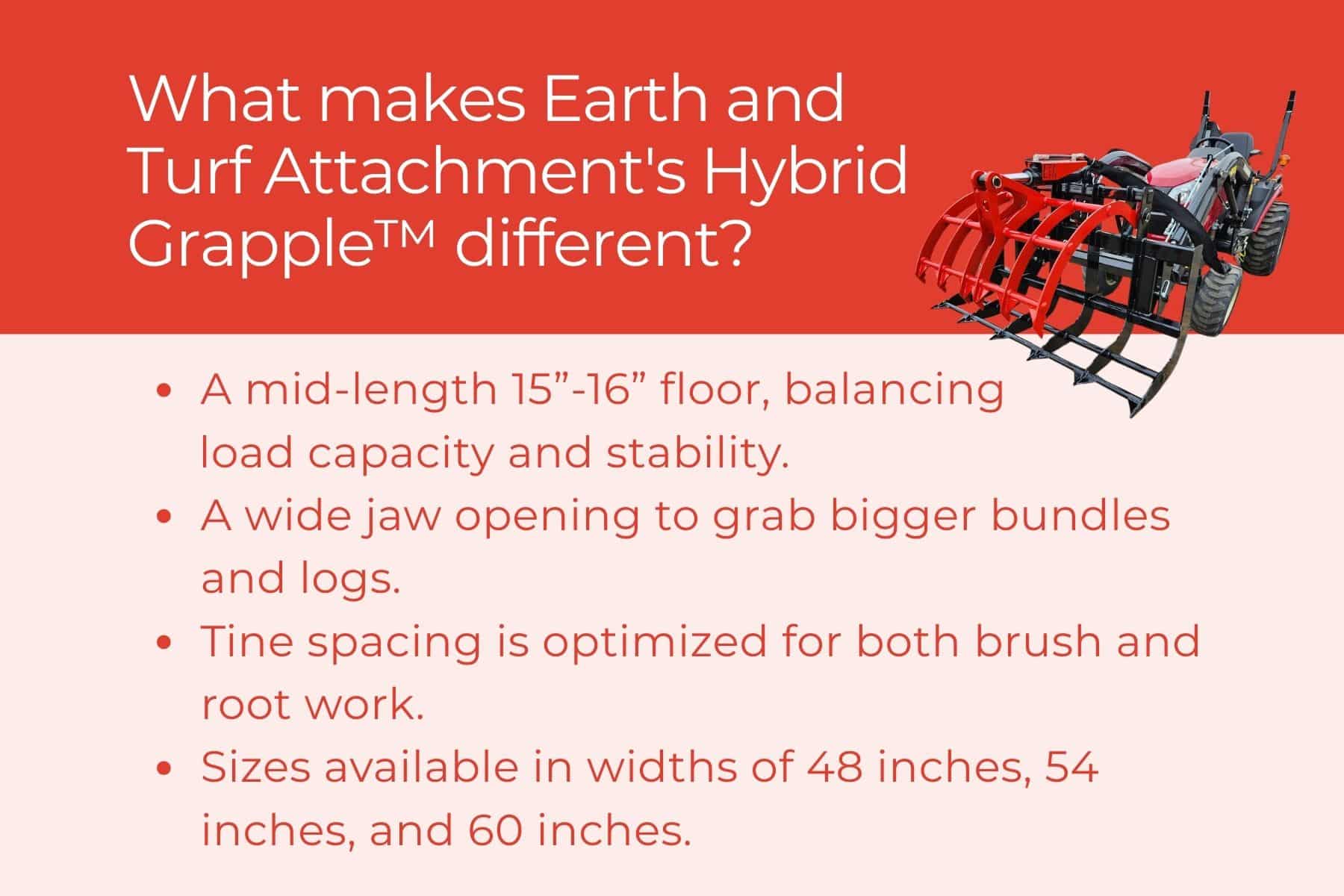

Spotlight on the Earth & Turf Attachments Hybrid Grapple™

When it comes to doing it all, a multi-purpose or hybrid grapple is the way to go. If you need a grapple to handle multiple tasks, why not get the best there is?

Earth and Turf Attachment’s patented Hybrid Grapple™ is explicitly designed for compact and sub-compact tractors. What makes it different?

- A mid-length 15”-16” floor, balancing load capacity and stability.

- A wide jaw opening to grab bigger bundles and logs.

- Tine spacing is optimized for both brush and root work.

- Sizes available in widths of 48 inches, 54 inches, and 60 inches.

It’s a true all-in-one option that offers a blend of strength, utility, and compact-friendly design, without compromising performance.

If you’re looking for a grapple that’s as versatile as your tractor, the Hybrid Grapple™ is worth a closer look.

Conclusion

The right grapple can transform how you use your compact tractor. Whether you're managing acres of brush, cleaning up after storms, or just keeping a tidy property, there's a grapple built for the job. By understanding your tractor’s capabilities and matching them to your workload, you’ll increase efficiency, work more effectively, and rest easier.

At Earth and Turf Attachments, we’re passionate about designing attachments for compact and subcompact tractors that let you work smarter, not harder! Since 1997, we’ve been focused on helping our customers maximize the capabilities of their tractors. Everything we build is proudly made in America—more specifically, in Lancaster County, Pennsylvania, known for its excellent work ethic and high-quality workmanship.

Contact us today and let us help you find the perfect grapple for the job!